The Margaret Anne was a badly weathered wreck of a hull sitting in a paddock at Wagga Wagga NSW.

The landholder wanted to burn the wreck as he considered it beyond repair.

Fortunately he offered it to the Traditional Boat Squadron before doing so.

I already had a 10 foot 6 inch clinker boat called Whimbrel so was not interested in another.

As nobody wanted to visit the boat I went to Wagga with a trailer and brought it home where it sat in our carport, waiting for a new owner.

After two years of nobody coming forward and me ‘Not looking’, and ‘I don’t want to see it’, I finally gave in and commenced restoration."

The hull was basically complete, but badly dried out and weathered. Fortunately it was in original, untouched condition which was the ideal way to start a restoration. This influenced my decision to take on the restoration as much original information was still present. The seams had opened up with six planks split along the rivet lines. The topsides were rotted and the keel was canted over to port from the boat laying on its side. All the original bits, flooring ply, coamings, etc, were still with the boat, to enable their use as templates. The engine appeared complete but was dismantled and the rusty components were kept in a bucket of water.

Plank split along rivet line.

Planks split and lifting away from transom.

Preliminary and tentative paint removal to establish extent of damage. A protective shaped length of PVC downpipe was removed from the keel to enable past Teredo worm holes to be treated by injecting two part epoxy into all the holes. Note all the miscellaneous parts under the boat.

Planks being removed in pairs from garboard down for sanding and replacement as necessary. This paired process was utilised to help preserve the hull shape and eliminate warping or distortion while the hull was opened. New planks of Meranti (Philippine Mahogany or Luan) 6 inches wide by ½ inch thick by 16 foot long clear planks were obtained from Trend Timbers at Penrith NSW .

The original planks were used as templates allowing for shrinkage and splitting.

Garboard and Plank 3 replaced. Rotted ribs along the waterline being repaired by splicing and gluing shaped reinforcing pieces. The transom was moved forward 1 ½ inches to eliminate split ends and damaged screw holes.

One of the best views of the hull. The lovely lines of the boat are starting to be seen. The newer planks can be seen with the lighter colour. (Garboard, fourth and sixth from keel). The planks were all bent into shape without steaming. Garboard - just! A 4 inch split at the bows needed to be repaired successfully by splining and gluing (thin sliver of wood shaped to match the split. The split can be seen at the top left of the hull near the bows

Progressing down the hull.

All planks fitted. The bottom plank is original and it can be seen how much the hull has been shortened.

Riveting the nails over the roves, a tedious job! All the original copper nails and roves were replaced as they had corroded and eroded more that half their thickness. A bead of black Sikaflex was applied between the planks before clamping up. There were 1200 nails overall, with one complete plank being finished per night.

My ‘Dolly Girl’ being a great help by holding a steel ‘anvil’ against the heads of the nails while riveting over the nails to clamp the planks together.

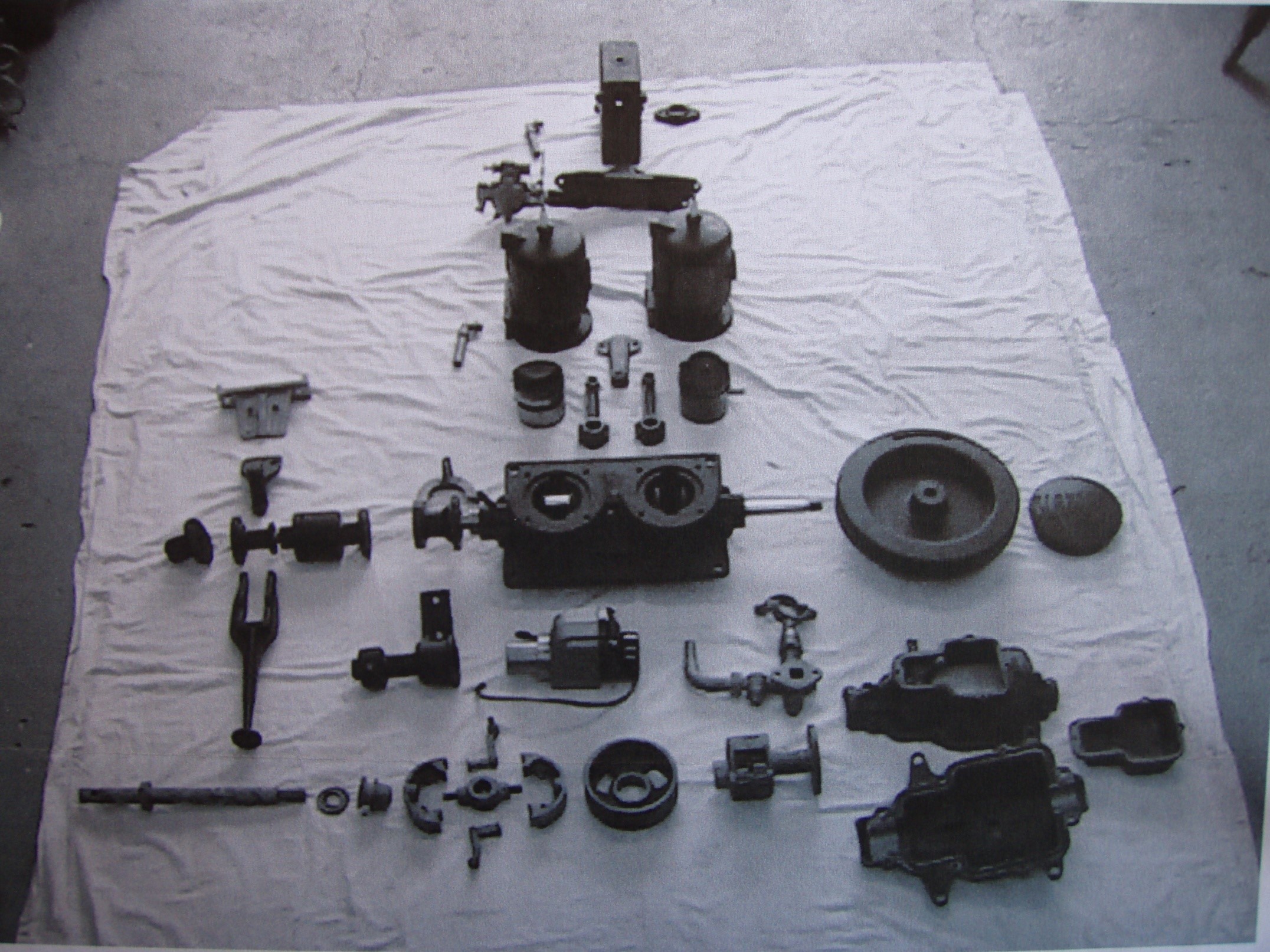

The complete engine components before assembly. They were abrasive blasted and black etch primed. All components appeared to e in good condition. One cylinder had rust build up in the water jacket that had pressured the inner cylinder wall slightly inwards and restriction the piston clearance. This distortion was honed out. Upon assembly it was also found that one piston was striking the bottom cylinder flange. It was caused by one bronze conrod having been compressed into an ‘S’ shape in the past and subsequently straightened. This resulted in the conrod being 1/8 inch too short. This possibly resulted in hydraulic lock from the engine taking a gutful of water in the past whilst still running. A spare conrod fixed the problem.

Nearly there. Note the wire string line running through the stern tube.

This enabled measurements to be taken to determine what packers were required to align the engine to the stern tube.

The stern tube hole was reamed out with a home made reamer made from a length of a 1 inch N. B. steel tube with ‘teeth’ cut in the end. A copper tube was then inserted to prevent water ingress as the skeg was shrunken and split. This shrinkage was considerable and resulted in the engine having to be realigned with packers.

It was decided to rename the ‘Margaret Anne’ to ‘Cormorant’.

In our River Murray trip planning SA requires all boats fitted with an engine to be registered. NSW registration requires that the registration number ends with an ‘N’. It was found that the German name for a cormorant was Kormoran, so our registration number became KRMRN, from the consonants. For no other reason than just because we could and it looked good!

We have no German connections and have nothing to do with the German raider ‘HSK Kormoran’.

So, ‘KRMRN’ it became!

So, the first engine fiddle and away we went!

‘Sea’ trials on Lake Burley Griffin, sans decking. The start of many adventures on the waters of Lake Burley Griffin, our home waters, Sussex Inlet for holidays and the Murray River in 2007.

We make a good team.

Finishing off the topsides. Using a cardboard template, four pieces of 3/8th inch marine ply made up the deck, joined midships. The coaming was the original, split but saveable with adhesive filling the cracks prior to painting.

The International Paints colours chosen were too brilliant for the heritage effect desired so they were diluted 50% with white to bring them to a more reasonable tone.

The canopy frame was made to match the original coaming profile, thereby enabling the original covering tarpaulin to be used. The canopy frame utilised billiard cues from Recycle and was completed in a week ready for our big River Murray adventure in 2007.

Seven months later – all complete, but with many ongoing refinements, additions and adjustments to come.

Our camping set up. We learned to live very neatly – a place for everything and everything in its place – mostly! The dome tent gave a little privacy and kept the mozzies away.. The starboard flag is for the Lower Murray from Wentworth down to Goolwa and the port one is for the Upper Murray from Wentworth to its source. We spent four months on the River and travelled 1200 kilometres on the Murray and 50 kilometres up the Darling.

Lunchtime on the River on a cold and windy day near Lock Seven.

Contrasted with -

Aaah - the serenity!

Comments are closed!